Toward an End to Microfiber Pollution

Since we first learned of the role we play in the spread of microfiber pollution in 2015, Patagonia has actively searched for partners to help end—or at least seriously curtail—the spread of synthetic fiber waste into the air and water.

We’ve long been familiar with the microplastics problem—the breakdown of plastic bottles, yogurt cups and fishing nets into streams, and then into the oceans in widening gyres of gunk that become part of the diets of marine birds and wildlife. Microplastic pollution is no longer confined to the oceans. According to the World Wildlife Fund, human beings every week are ingesting plastic waste in the air and water equivalent to the size of a credit card. Yes, plastic waste ends up in the stomachs of shorebirds, but also in human blood and breast milk.

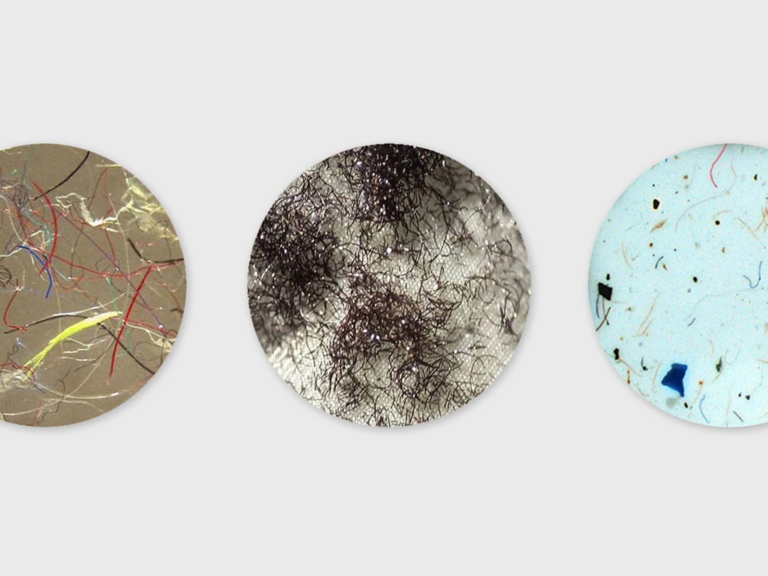

Microscopic views of microfibers. Photos: Bren School of Environmental Science and Management at UCSB

At 5 millimeters or less in length, microfiber particles from synthetic clothing—polyester, nylon, spandex, acrylic—are invisible or scarcely visible as single strands, yet 200,000 to 500,000 tons of fibers shed from clothing wend their way to the ocean floor every year. Annually, they contribute between 16 and 35 percent of the ocean’s microplastic pollution. Cleanup of so big a problem broken down into such tiny particulars is, as yet, not possible, which puts the onus, appropriately, on garment brands to prevent the spread of microfibers at the source.

Over the past eight years we have worked on several fronts to reduce the release of microfibers from our polyester and nylon clothes. We’ve improved product engineering and fabric construction to reduce shedding. Through our corporate venture capital arm, Tin Shed Ventures, we’ve invested in Matter, a startup that’s developing industry-scale filtration technology to capture microfibers during textile manufacturing. We’ve advocated a wardrobe of fewer clothes of higher quality. We’ve encouraged customers to wash their clothes less frequently, and in cold water on the gentle cycle. Cold-water washing on a gentle cycle alone, according to the Plastics Lab of the NGO Ocean Wise, can reduce shedding by 70 percent. (A notable exception is laminated garments like waterproof shells, which are far less likely to shed because the lamination process glues the fabric to the membrane and locks everything in place. Though shell care does call for regular washes with warm water to prolong your gear’s life, without that care, your shell won’t last for the long haul, and you’ll end up needing to buy a new one, which requires more resources overall.) We also introduced a GUPPYFRIEND® Washing Bag for washing synthetic clothes that keeps some of the fibers from migrating into wastewater. And we’ve worked with Ocean Wise and the city of Vancouver on the potential for municipal filtration systems to capture more of the microfibers released every day from clothes washers.

Ocean Wise has been our primary partner and advisor for the past eight years, but we have had key help from two universities. The Bren School of Environmental Science and Management at University of California, Santa Barbara, has provided critical information on how much garments shed in various types of washers. North Carolina State University helped us develop standardized test protocols to evaluate the extent of shedding.

For the past three years we’ve worked closely (and productively) with Samsung Electronics to help them introduce significant improvements to home washing machines. Our collaboration began almost by accident: at the behest of Sean Kim, our environmental lead in Korea, and Soo Jin Kim, Samsung’s head of sustainability, I spoke virtually with a group of Samsung executives about environmental impacts we found the most challenging. I was in the process of bemoaning our inability to interest an appliance manufacturer in addressing the microfiber problem when I remembered who I was talking to and rudely blurted out, “Say, you make washing machines.”

Their immediate response was deadpan, but I think the engineers among them were already ahead of me. In the weeks that followed, Samsung’s engineers peppered us with questions. We introduced them to Ocean Wise, and soon teams from the three respective organizations were testing prototypes. Samsung had already developed a technology called “Ecobubble” which helps the detergent dissolve more easily in water so that it foams better. This means that water does not have to be heated up and mechanical friction can be kept to a minimum level and still get a high washing performance. They adapted similar technology to reduce microfiber shedding. We were impressed by Samsung’s commitment and by their speed. In January 2023, at the Consumer Electronics Show (CES), they introduced a new washer with a Less Microfiber Cycle that reduces emissions by 54 percent.

Samsung has now brought to market a Less Microfiber Filter that can be attached easily to any existing front-loading washer.* Ocean Wise has verified that this filter reduces microfiber shedding by 98 percent. It was introduced into the Korean market in May 2023, and in Europe and North America a few months later.

Samsung’s new filter can be fitted to most of the brand’s washers to reduce microplastic shedding by 98 percent. Photo: Samsung

We can’t thank Samsung’s people enough for the quality of both their engineering and sustainability efforts, which have had support from throughout the company—from the chairman to the seasoned engineers to gifted younger employees who helped make this advance possible. A collaboration between a global electronics giant and a company that touts Earth as its sole shareholder may be an unlikely combination, but many such collaborations are needed for the future.

Competitors are now trying to follow Samsung’s lead with plans to introduce washers that reduce microfiber shedding. An important next step is to reduce microfiber emissions into the air from clothes dryers.

Radical new appliance technology from Samsung and others is a major development but by no means the only way to curtail microfiber pollution. Buying better-quality and fewer clothes is the most “efficient” way to reduce your microfiber impact. The search for better engineering and construction continues, as does further research into where, when and how microfibers are released into the water and atmosphere, or our one and only life zone.

*Recommended for use with Samsung washers (except 25″ models). If filter is used with non-Samsung washing machines, Samsung’s warranty is limited to the filter only.